Cost to Replace Engine Bearings: What to Expect & Save

📋 Table of Contents

The cost to replace engine bearings typically ranges from $2,000 to $4,000 or more, significantly depending on labor hours, parts quality, and engine type. This vital repair prevents catastrophic engine failure but requires extensive labor due to engine removal and meticulous reassembly.

🎯 Key Takeaways

- Expect $2,000-$4,000+ for engine bearing replacement due to high labor.

- Early diagnosis prevents further damage, saving significant repair costs.

- Always get multiple quotes from reputable mechanics for best pricing.

- Professional replacement is crucial; DIY carries high risks and complexity.

- Evaluate repair cost versus vehicle value; engine replacement might be better.

<p>Have you ever heard a strange knocking sound coming from your engine? It's a sound that makes most car owners cringe. Often, this noise points to a serious issue lurking within: failing engine bearings. Ignoring it can lead to catastrophic engine damage, turning a potentially repairable problem into a need for a full engine replacement.</p>

<p>Understanding the cost to replace engine bearings is crucial for any car owner. It helps you prepare financially and make informed decisions. This blog post will guide you through what engine bearings are, how to spot their failure, and give you a clear breakdown of what you can expect to pay for parts and labor. We want to empower you with knowledge so you can save money and keep your vehicle running smoothly.</p>

<h2>Understanding Engine Bearings: Function, Types, and Failure Signs</h2>

<h3>What Do Engine Bearings Actually Do?</h3>

<p>Think of engine bearings as tiny but mighty guardians inside your engine. Their main job is to reduce friction between moving metal parts. They support your engine's crankshaft and connecting rods as they spin at thousands of revolutions per minute. Without them, metal would grind against metal. This would quickly cause immense heat and destruction.</p>

<p>These bearings are typically made of a soft, anti-friction alloy material. This material is layered over a stronger steel or bronze backing. There are two main types: <strong>main bearings</strong> and <strong>rod bearings</strong>. Main bearings support the crankshaft within the engine block. Rod bearings connect the crankshaft to the connecting rods, which attach to the pistons. Both are critical for your engine’s smooth and long life. They ensure proper oil flow and prevent wear. Ignoring their importance is like asking your engine to run without proper lubrication.</p>

<h3>Spotting Trouble: Common Signs of Failing Engine Bearings</h3>

<p>Your engine often gives clear warnings when its bearings are going bad. The most common and alarming sign is a distinct <strong>knocking sound</strong>. This is often called “rod knock” and it usually gets louder when the engine is cold or when you accelerate. It sounds like someone tapping a hammer inside your engine. This noise comes from the excessive clearance between the worn bearing and its shaft. It’s a serious sign that needs immediate attention.</p>

<p>Other symptoms can include a noticeable <strong>drop in oil pressure</strong>. You might see your oil pressure warning light come on. Worn bearings allow more oil to escape, leading to lower pressure. You might also find <strong>metal flakes or shavings</strong> in your engine oil when you check the dipstick or during an oil change. This is a sure sign of internal wear. Finally, a general <strong>loss of engine power</strong> or increased vibration can also point to bearing issues. If you notice any of these signs, don’t delay. Driving with failing bearings can quickly lead to complete engine failure. Getting it checked early can save you a lot of money.</p>

<h2>Detailed Breakdown of Engine Bearing Replacement Costs: Parts & Labor</h2>

<h3>The Cost of Parts: What You'll Pay For</h3>

<p>When replacing engine bearings, you're not just buying a single part. You'll need a set of <strong>main bearings</strong> and a set of <strong>rod bearings</strong>. These typically come in sets, specific to your vehicle's make and model. The cost for these bearing sets usually ranges from <em>$100 to $300</em>, depending on your car. High-performance or specialty vehicles might have higher part costs.</p>

<p>However, bearings are only part of the equation. You will also need a <strong>full engine gasket set</strong> to reassemble everything, costing <em>$50 to $200</em>. Don't forget new <strong>engine oil</strong> and an <strong>oil filter</strong>, which can add another <em>$30 to $80</em>. In many cases, if the bearings failed due to lack of lubrication or wear, the crankshaft might also need attention. This could involve <strong>crankshaft polishing or grinding</strong> at a machine shop, which can add <em>$100 to $400</em> to your total parts bill. Always choose reputable brands or OEM (Original Equipment Manufacturer) parts for durability. Skimping on quality now can lead to another costly repair very soon.</p>

<ul>

<li>Main and Rod Bearing Sets: <strong>$100 – $300</strong></li>

<li>Full Gasket Set: <strong>$50 – $200</strong></li>

<li>Engine Oil & Filter: <strong>$30 – $80</strong></li>

<li>Crankshaft Machine Work (if needed): <strong>$100 – $400</strong></li>

</ul>

<h3>Labor Costs: Why It's Often the Biggest Expense</h3>

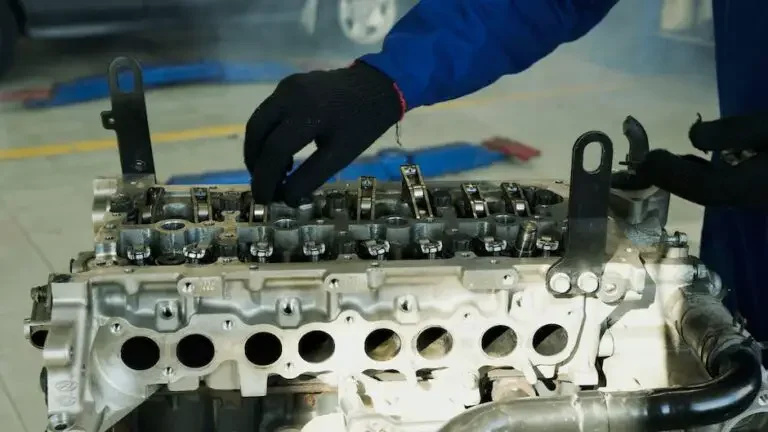

<p>Replacing engine bearings is a very labor-intensive job. It often requires removing the engine from the vehicle entirely. This makes it one of the more expensive mechanical repairs. A skilled mechanic needs to disassemble a significant portion of your engine. This includes removing the oil pan, connecting rods, and crankshaft to access the bearings. Then they must carefully install the new ones and reassemble everything.</p>

<p>The total time for this job can range widely, typically from <em>10 to 20 hours</em>. This depends heavily on your specific vehicle. Some cars, like front-wheel-drive vehicles with transversely mounted engines, are much harder to work on. Mechanics typically charge <em>$75 to $150 per hour</em>, sometimes even more in metropolitan areas. This means labor costs alone can easily fall between <strong>$750 and $3000 or more</strong>. Factors like engine size, make, and whether the engine needs to be pulled out significantly impact this cost. Always get multiple quotes from trusted shops. Look for mechanics specializing in engine repair to ensure quality work.</p>

Key Factors Influencing Your Total Engine Bearing Repair Expense

Understanding what drives the final bill for engine bearing replacement is crucial. It’s rarely a one-size-fits-all cost, as several variables come into play.

1. Extent of Damage & Engine Type

The severity of the damage is perhaps the biggest cost driver. If caught early, you might only need new bearings. However, if the bearings have spun or severely worn, they can damage the crankshaft journals, connecting rods, or even the engine block. A crankshaft that needs to be ground or replaced will add hundreds, even thousands, to your repair bill. Furthermore, the type of engine matters. A simple 4-cylinder engine is often easier and quicker to work on than a complex V6 or V8, which has more bearings and potentially less accessible components, thus impacting labor time and parts cost.

2. Labor Rates & Parts Quality

Labor is a significant portion of this repair, given the extensive work required. Mechanic labor rates vary wildly based on your geographic location (e.g., urban centers typically cost more than rural areas) and the shop’s expertise. A dealership will almost always charge more per hour than an independent specialist. When it comes to parts, you have choices: Original Equipment Manufacturer (OEM) parts are usually more expensive but offer guaranteed fit and quality. Aftermarket bearings can be more affordable, but quality can vary. It’s often a wise investment to use high-quality bearings to ensure the repair lasts.

When to Repair vs. Replace Your Engine: A Cost-Benefit Analysis

Faced with a substantial engine bearing repair bill, many car owners grapple with a tough question: should I fix it, or is it time for a new engine (or even a new car)? This decision involves more than just the immediate repair cost.

Considering the Vehicle’s Overall Value

Start by assessing your vehicle’s current market value and overall condition. If your car is an older model with high mileage, significant rust, or other major mechanical issues looming (like a failing transmission or suspension), investing thousands into a bearing repair might not be financially sound. For example, spending $3,000 on bearing replacement for a car that’s only worth $4,000 post-repair might not make sense. However, if your car is relatively new, well-maintained, and has a high resale value, the repair is often the more economical choice.

Calculating the Long-Term Cost-Effectiveness

Don’t just look at the repair cost; consider the future. A properly repaired engine can give you many more years of reliable service. On the other hand, a used replacement engine might be cheaper initially but comes with its own unknowns regarding its history and potential for future issues. A remanufactured engine offers a balance, often with a warranty. Here’s how to think it through:

- Get a comprehensive quote for the engine bearing repair, detailing parts and labor.

- Research the cost of a used engine (with installation) and a remanufactured engine (with installation) for your specific vehicle.

- Assess your vehicle’s overall health: Are there other expensive repairs on the horizon?

- Compare the total costs against your vehicle’s market value if it were in excellent condition. If the repair cost significantly exceeds 50-70% of the car’s value, a replacement engine or even a new vehicle might be a better investment.

Conclusion: Make an Informed Decision for Your Engine’s Future

Dealing with failing engine bearings can be daunting, both mechanically and financially. We’ve seen that the cost to replace engine bearings varies widely, influenced by the extent of damage, your engine type, and labor rates. Making the right choice often comes down to weighing the repair cost against your vehicle’s overall value and the long-term cost-effectiveness of each option.

Don’t hesitate to get multiple opinions and detailed quotes from trusted mechanics. Discuss the pros and cons of repairing versus replacing your engine thoroughly. By staying informed and acting proactively at the first signs of trouble, you can make the best decision to keep your vehicle running smoothly or wisely move on to your next automotive adventure.

💬 Quick Questions & Answers

What are engine bearings?

Engine bearings are critical components that reduce friction between moving parts, allowing the crankshaft and connecting rods to spin smoothly and efficiently.

How much does labor cost for engine bearing replacement?

Labor typically accounts for the largest portion, ranging from $1,500 to $3,000+ due to the intensive work involved in engine removal and precise reassembly.

Can I drive with bad engine bearings?

No, driving with bad engine bearings is highly risky and can quickly lead to catastrophic engine failure and much more expensive, irreparable damage.

What are common signs of bad engine bearings?

Common signs include a distinct knocking or rattling sound, especially noticeable during acceleration, and potentially low oil pressure readings on your dashboard.

Are engine bearing parts expensive?

The parts themselves are relatively inexpensive, often costing $100-$300 for a full set, but high-performance or specialized sets can cost more.

❓ Frequently Asked Questions

What exactly contributes to the high cost of engine bearing replacement?

The high cost primarily stems from the extensive labor required. Mechanics must typically remove the engine, completely disassemble significant components to access the bearings, and then meticulously reassemble everything, often taking 15-30 hours or more of skilled work.

How does engine type impact the cost of replacing bearings?

Engine type significantly affects cost because complex engines (V6, V8, diesel, turbocharged) often require more labor hours and specialized tools for disassembly and reassembly. Parts for these engines can also be more expensive than for simpler inline 4-cylinder engines due to their design and fewer available aftermarket options.

What is the average lifespan of engine bearings, and how can I extend it?

Engine bearings are designed to last the lifetime of the engine, typically 150,000-200,000 miles or more, but poor maintenance drastically shortens this. Regular oil changes with the correct viscosity, avoiding low oil levels, and not over-revving a cold engine are crucial practices for maximizing their longevity.

Should I replace other components when replacing engine bearings?

Yes, it’s highly recommended to inspect and potentially replace other related components while the engine is already apart for bearing access. This often includes the oil pump, main seals, connecting rod bolts, and sometimes even piston rings to ensure long-term reliability and prevent future costly repairs.

What are the risks of choosing cheap engine bearings or attempting a DIY replacement?

Opting for cheap bearings or attempting a DIY replacement without proper expertise carries significant risks, including improper installation, premature failure of the new bearings, and even causing further, irreparable damage to the crankshaft or engine block. Precision and specific torque settings are paramount for this critical repair.

Is engine bearing replacement always the best solution, or should I consider a new engine?

Engine bearing replacement is ideal if the crankshaft is undamaged and the overall engine block is in good condition. However, if the crankshaft is heavily scored, the engine has other significant internal issues, or the repair cost approaches 75% of your vehicle’s value, a full engine replacement or even purchasing a different vehicle might be more cost-effective in the long run.